Page 7 - Application Guide Semiconductor Fuse Link

P. 7

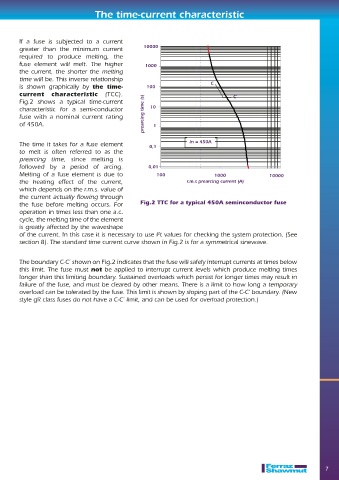

The time-current characteristic

If a fuse is subjected to a current

10000

greater than the minimum current

required to produce melting, the

fuse element will melt. The higher 1000

the current, the shorter the melting

time will be. This inverse relationship

C

is shown graphically by the time- 100

current characteristic (TCC). C’

Fig.2 shows a typical time-current

characteristic for a semi-conductor 10

fuse with a nominal current rating prearcing time (s)

of 450A. 1

In = 450A

The time it takes for a fuse element

0,1

to melt is often referred to as the

prearcing time, since melting is

followed by a period of arcing. 0,01

Melting of a fuse element is due to 100 1000 10000

the heating effect of the current, r.m.s prearcing current (A)

which depends on the r.m.s. value of

the current actually fl owing through

the fuse before melting occurs. For Fig.2 TTC for a typical 450A seminconductor fuse

operation in times less than one a.c.

cycle, the melting time of the element

is greatly affected by the waveshape

2

of the current. In this case it is necessary to use I t values for checking the system protection. (See

section 8). The standard time current curve shown in Fig.2 is for a symmetrical sinewave.

The boundary C-C’ shown on Fig.2 indicates that the fuse will safely interrupt currents at times below

this limit. The fuse must not be applied to interrupt current levels which produce melting times

longer than this limiting boundary. Sustained overloads which persist for longer times may result in

failure of the fuse, and must be cleared by other means. There is a limit to how long a temporary

overload can be tolerated by the fuse. This limit is shown by sloping part of the C-C’ boundary. (New

style gR class fuses do not have a C-C’ limit, and can be used for overload protection.)

7