Page 129 - Din prodcuts 2020

P. 129

1/119 1

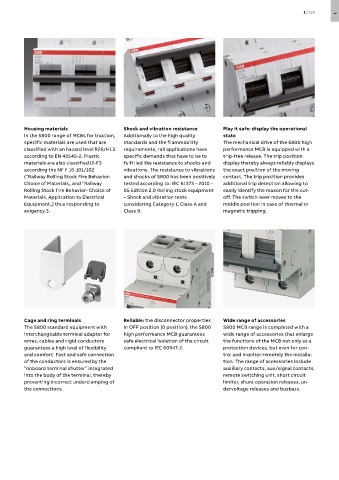

Housing materials Shock and vibration resistance Play it safe: display the operational

In the S800 range of MCBs for traction, Additionally to the high quality state

specific materials are used that are standards and the fl ammability The mechanical drive of the S800 high

classified with an hazard level R26/HL3 requirements, rail applications have performance MCB is equipped with a

according to EN 45545-2. Plastic specific demands that have to be to trip-free release. The trip position

materials are also classified I2-F3 fulfi lled like resistance to shocks and display thereby always reliably displays

according the NF F 16-101/102 vibrations. The resistance to vibrations the exact position of the moving

(“Railway Rolling Stock Fire Behavior- and shocks of S800 has been positively contact. The trip position provides

Choice of Materials„ and “Railway tested according to: IEC 61373 – 2010 – additional trip detection allowing to

Rolling Stock Fire Behavior- Choice of 05 Edition 2.0 Rolling stock equipment easily identify the reason for the cut-

Materials, Application to Electrical – Shock and vibration tests off. The switch lever moves to the

Equipment„) thus responding to considering Category 1, Class A and middle position in case of thermal or

exigency 3. Class B. magnetic tripping.

Cage and ring terminals Reliable: the disconnector properties Wide range of accessories

The S800 standard equipment with In OFF position (0 position), the S800 S800 MCB range is completed with a

interchangeable terminal adapter for high performance MCB guarantees wide range of accessories that enlarge

wires, cables and rigid conductors safe electrical isolation of the circuit the functions of the MCB not only as a

guarantees a high level of flexibility compliant to IEC 60947-2. protection devices, but even for con-

and comfort. Fast and safe connection trol and monitor remotely the installa-

of the conductors is ensured by the tion. The range of accessories include

“onboard terminal shutter” integrated auxiliary contacts, aux/signal contacts,

into the body of the terminal, thereby remote switching unit, short circuit

preventing incorrect underclamping of limiter, shunt operation releases, un-

the connections. dervoltage releases and busbars.