Page 29 - VSD_Brochure_31102023

P. 29

WATER DRIVES

Optimising the flow of water and wastewater in your

pumping solutions

The ACQ580 water and wastewater drive is built to help users, designers, OEMs, system

integrators and EPC professionals secure pumping of water and wastewater in

municipal utilities, pumping stations, industrial wastewater facilities, desalination plants

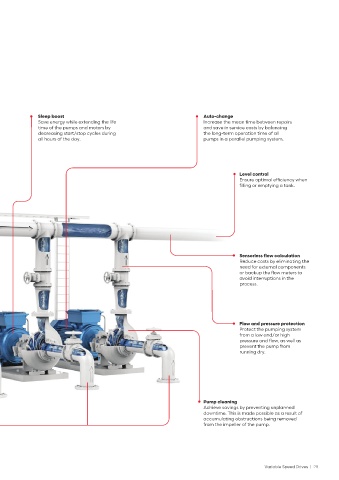

and irrigation environments. It offers long-term, technically-compatible drive solutions Sleep boost Auto-change

Save energy while extending the life Increase the mean time between repairs

supported by full service and support.

time of the pumps and motors by and save in service costs by balancing

decreasing start/stop cycles during the long-term operation time of all

all hours of the day. pumps in a parallel pumping system.

Level control

Ensure optimal efficiency when

filling or emptying a tank.

Soft pipe filling

Increase the lifetime of the piping

and pump system by avoiding

pressure peaks.

Sensorless flow calculation

Reduce costs by eliminating the

Quick ramps need for external components

Extend the lifecycle of submersible or backup the flow meters to

pumps by reducing wear of the avoid interruptions in the

mechanical parts using ramp sets to process.

accelerate and decelerate the pumps.

Flow and pressure protection

Protect the pumping system

from a low and/or high

pressure and flow, as well as

prevent the pump from

Pump priority running dry.

Achieve energy savings with optimal

pump alternation by running the higher

capacity pumps when the consumption

rate is higher.

Pump cleaning

Achieve savings by preventing unplanned

downtime. This is made possible as a result of

accumulating obstructions being removed

Anti-cavitation Multi-pump control from the impeller of the pump.

Extend the pump lifetime and secure Ensure stable and uninterrupted production with

the process by detecting cavitation and multi-pump controls by optimising the speed and

ensuring optimal pump speed. number of running pumps.

28 | Variable Speed Drives Variable Speed Drives | 29