Page 220 - dehn-catalogue-lightning-protection_3

P. 220

Protection against Step and Touch Voltage

IEC/EN 62305-3 points out that in special cases the risk of step and touch The surge withstand capability of 100 kV (1.2/50 μs) is achieved by a spe-

voltage outside a building may be extremely high near the down conduc- cial cross-linked polyethylene insulation (XLPE). Unless additional mea-

tors, although there is a lightning protection system in accordance with sures are taken, high impulse voltages cause sparkover on insulating sur-

the current state of standardisation. faces. This effect is known as creeping discharge. If the creeping dischar-

Special cases are, for example, if bare/uninsulated down conductors and ge inception voltage is exceeded, a surface discharge will be initiated,

lightning protection earth electrodes are installed near the entrance or which can easily spark over a distance of several metres to earthed parts.

sheltering areas of buildings with high visitor frequency, such as theatres, In order to avoid the occurrence of creeping discharges even during rain,

cinemas, shopping centres, etc. Buildings or structures with public access the CUI conductor additionally has a shield which keeps the conductor

(e.g. shelters) which are particularly exposed (lightning endangered) may dry. Figure 4 shows this shield on the conductor and the drops after

also require protection measures against step and touch voltage. the rain test.

Protection against touch voltage

Touch voltage means a life-threatening voltage that affects a person who

touches the down conductor while standing on the ground within a dis-

tance of about 1 m from the down conductor. The current flows through

the hand into the body and down to the feet (see Figures 1/2).

The hazardous area for people outside of the building is defined as an

area of 3 m around the down conductor and from ground level up to a

height of approx. 3 m.

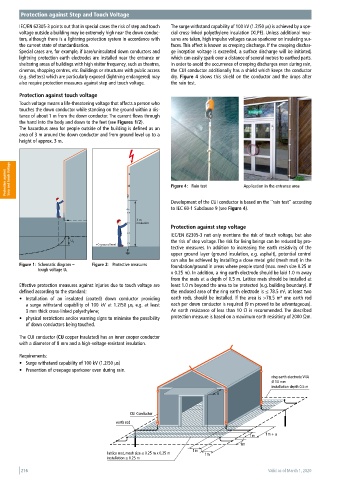

Protection against Step and Touch Voltage Figure 4: Rain test Application in the entrance area HVI power Conductor

Development of the CUI conductor is based on the ‘’rain test’’ according

to IEC 60-1 Subclause 9 (see Figure 4).

3 m

insulation

Protection against step voltage

IEC/EN 62305-3 not only mentions the risk of touch voltage, but also

the risk of step voltage. The risk for living beings can be reduced by pro-

U T

±0 ground level

tective measures. In addition to increasing the earth resistivity of the

upper ground layer (ground insulation, e.g. asphalt), potential control

can also be achieved by installing a close metal grid (mesh mat) in the

Figure 1: Schematic diagram – Figure 2: Protective measures foundation/ground in areas where people stand (max. mesh size 0.25 m

tough voltage Ut

x 0.25 m). In addition, a ring earth electrode should be laid 1.0 m away

from the mats at a depth of 0.5 m. Lattice mats should be installed at

Effective protection measures against injuries due to touch voltage are least 1.0 m beyond the area to be protected (e.g. building boundary). If

defined according to the standard: the enclosed area of the ring earth electrode is ≤ 78.5 m², at least two

• Installation of an insulated (coated) down conductor providing earth rods, should be installed. If the area is >78.5 m² one earth rod

a surge withstand capability of 100 kV at 1.2/50 μs, e.g. at least each per down conductor is required (9 m proved to be advantageous).

3 mm thick cross-linked polyethylene; An earth resistance of less than 10 Ω is recommended. The described

• physical restrictions and/or warning signs to minimise the possibility protection measure is based on a maximum earth resisitivty of 2000 Ωm.

of down conductors being touched.

The CUI conductor (CU copper Insulated) has an inner cooper conductor

with a diameter of 8 mm and a high-voltage-resistant insulation.

Requirements:

• Surge withstand capability of 100 kV (1.2/50 µs)

• Prevention of creepage sparkover even during rain.

ring earth electrode V4A

Ø 10 mm

installation depth 0.5 m

a

CUI Conductor

earth rod

1 m 1 m + a

1 m

1 m

lattice mat, mesh size ≤ 0.25 m x 0.25 m 1 m

installation ≤ 0.25 m

216 Valid as of March 1, 2020