Page 117 - dehn-catalogue-safety-equipment_0

P. 117

NS / MS Dry Cleaning Kit MS Damp Cleaning Kit MS Combined Cleaning Kit PPE – Personal Protective Equipment Covering Material

Live W orking

Cleaning Equipment

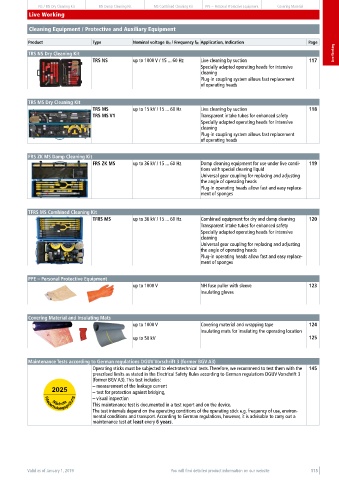

Cleaning Equipment / Protective and Auxiliary Equipment

Product Type Nominal voltage UN / Frequency fN Application, Indication Page

TRS NS Dry Cleaning Kit Live Working

TRS NS up to 1000 V / 15 ... 60 Hz Live cleaning by suction 117

Specially adapted operating heads for intensive

cleaning

Plug-in coupling system allows fast replacement

of operating heads

TRS MS Dry Cleaning Kit

TRS MS up to 15 kV / 15 ... 60 Hz Live cleaning by suction 118

TRS MS V1 Transparent intake tubes for enhanced safety

Specially adapted operating heads for intensive

cleaning

Plug-in coupling system allows fast replacement

of operating heads

FRS ZK MS Damp Cleaning Kit

FRS ZK MS up to 36 kV / 15 ... 60 Hz Damp cleaning equipment for use under live condi- 119

tions with special cleaning liquid

Universal gear coupling for replacing and adjusting

the angle of operating heads

Plug-in operating heads allow fast and easy replace-

ment of sponges

TFRS MS Combined Cleaning Kit

TFRS MS up to 36 kV / 15 ... 60 Hz Combined equipment for dry and damp cleaning 120

Transparent intake tubes for enhanced safety

Specially adapted operating heads for intensive

cleaning

Universal gear coupling for replacing and adjusting

the angle of operating heads

Plug-in operating heads allow fast and easy replace-

ment of sponges

PPE – Personal Protective Equipment

up to 1000 V NH fuse puller with sleeve 123

Insulating gloves

Covering Material and Insulating Mats

up to 1000 V Covering material and wrapping tape 124

Insulating mats for insulating the operating location

up to 50 kV 125

Maintenance Tests according to German regulations DGUV Vorschrift 3 (former BGV A3)

Operating sticks must be subjected to electrotechnical tests. Therefore, we recommend to test them with the 145

prescribed limits as stated in the Electrical Safety Rules according to German regulations DGUV Vorschrift 3

(former BGV A3). This test includes:

2025 – measurement of the leakage current

– test for protection against bridging,

Wiederholungsprüfung – visual inspection

Nächste

This maintenance test is documented in a test report and on the device.

The test intervals depend on the operating conditions of the operating stick e.g. frequency of use, environ-

mental conditions and transport. According to German regulations, however, it is advisable to carry out a

maintenance test at least every 6 years.

Valid as of January 1, 2019 You will find detailed product information on our website 115