Page 276 - 35_DS702_E_2014_Lightning_Protection_Guide

P. 276

In modern biogas plants, biodegradable organic substrates precautions and protection measures, potential risk sources

such as manure, dung, grass, straw, green waste, residues of which may cause failure or a dangerous event are considered

the sugar, wine and beer production, leftovers and grease are in a risk analysis according to the German Federal Immission

fermented in an air-tight container (fermenter). In this oxygen- Control Act (BImSchG) / Ordinance on Industrial Safety and

free atmosphere, bacteria produce biogas from the ferment- Health (BetrSichV).

able, organic biomass components. This bio gas is used to gen- The German Safety Regulations for Agricultural Biogas Plants

erate heat and electricity. published by the German Agricultural Professional Association

as well as the German BGR 104 specify that measures which

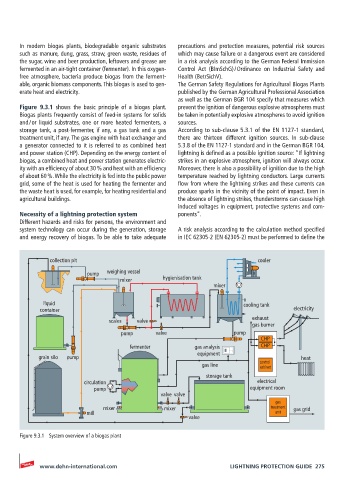

Figure 9.3.1 shows the basic principle of a biogas plant. prevent the ignition of dangerous explosive atmospheres must

Biogas plants frequently consist of feed-in systems for solids be taken in potentially explosive atmospheres to avoid ignition

and / or liquid substrates, one or more heated fermenters, a sources.

storage tank, a post-fermenter, if any, a gas tank and a gas According to sub-clause 5.3.1 of the EN 1127-1 standard,

treatment unit, if any. The gas engine with heat exchanger and there are thirteen different ignition sources. In sub-clause

a generator connected to it is referred to as combined heat 5.3.8 of the EN 1127-1 standard and in the German BGR 104,

and power station (CHP). Depending on the energy content of lightning is defined as a possible ignition source: “If lightning

biogas, a combined heat and power station generates electric- strikes in an explosive atmosphere, ignition will always occur.

ity with an efficiency of about 30 % and heat with an efficiency Moreover, there is also a possibility of ignition due to the high

of about 60 %. While the electricity is fed into the public power temperature reached by lightning conductors. Large currents

grid, some of the heat is used for heating the fermenter and flow from where the lightning strikes and these currents can

the waste heat is used, for example, for heating residential and produce sparks in the vicinity of the point of impact. Even in

agricultural buildings. the absence of lightning strikes, thunderstorms can cause high

induced voltages in equipment, protective systems and com-

Necessity of a lightning protection system ponents”.

Different hazards and risks for persons, the environment and

system technology can occur during the generation, storage A risk analysis according to the calculation method specified

and energy recovery of biogas. To be able to take adequate in IEC 62305-2 (EN 62305-2) must be performed to define the

collection pit cooler

pump weighing vessel

mixer hygienisation tank

mixer

liquid cooling tank

container electricity

scales valve exhaust

gas burner

pump valve pump

CHP

fermenter gas analysis CHP

equipment

grain silo pump heat

gas line control

cabinet

storage tank

circulation electrical

pump equipment room

valve valve

gas

mixer mixer treatment gas grid

mill unit

valve

Figure 9.3.1 System overview of a biogas plant

www.dehn-international.com LIGHTNING PROTECTION GUIDE 275