Page 277 - 35_DS702_E_2014_Lightning_Protection_Guide

P. 277

relevant protection measures. The purpose of this risk analysis radius of the rolling sphere r

is to determine the risk resulting from direct and indirect light-

ning strikes for a structure including the persons and equip-

ment therein. If the risk is higher than the tolerable risk, light-

ning protection measures must be taken to minimise the risk

resulting from a lightning strike so that it is no longer higher

than the tolerable risk.

Supplement 2 of the German DIN EN 62305-3 (VDE 0185-305-3)

standard includes additional information on special build-

ings including requirements on lightning protection systems

for biogas plants. According to this supplement, biogas plants

should be protected by isolated air-termination and down-

conductor systems if it cannot be excluded that risks resulting

from ignitable sparks occur at contact and connecting points.

External lightning protection

The fermenter, which is available in different designs, is the

core of every biogas plant. Therefore, the required lightning

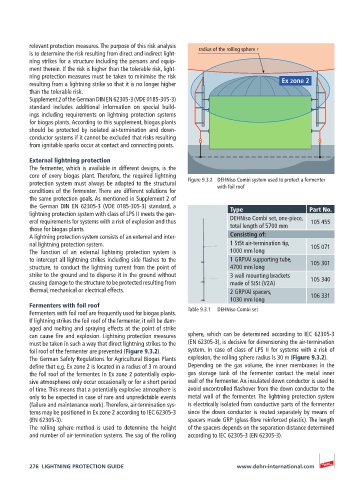

protection system must always be adapted to the structural Figure 9.3.2 DEHNiso Combi system used to protect a fermenter

with foil roof

conditions of the fermenter. There are different solutions for

the same protection goals. As mentioned in Supplement 2 of

the German DIN EN 62305-3 (VDE 0185-305-3) standard, a Type Part No.

lightning protection system with class of LPS II meets the gen-

eral requirements for systems with a risk of explosion and thus DEHNiso Combi set, one-piece, 105 455

those for biogas plants. total length of 5700 mm

A lightning protection system consists of an external and inter- Consisting of:

nal lightning protection system. 1 StSt air-termination tip, 105 071

The function of an external lightning protection system is 1000 mm long

to intercept all lightning strikes including side flashes to the 1 GRP/Al supporting tube, 105 301

structure, to conduct the lightning current from the point of 4700 mm long

strike to the ground and to disperse it in the ground without 3 wall mounting brackets

causing damage to the structure to be protected resulting from made of StSt (V2A) 105 340

thermal, mechanical or electrical effects. 2 GRP/Al spacers,

1030 mm long 106 331

Fermenters with foil roof

Fermenters with foil roof are frequently used for biogas plants. Table 9.3.1 DEHNiso Combi set

If lightning strikes the foil roof of the fermenter, it will be dam-

aged and melting and spraying effects at the point of strike

can cause fire and explosion. Lightning protection measures sphere, which can be determined according to IEC 62305-3

must be taken in such a way that direct lightning strikes to the (EN 62305-3), is decisive for dimensioning the air-termination

foil roof of the fermenter are prevented (Figure 9.3.2). system. In case of class of LPS II for systems with a risk of

The German Safety Regulations for Agricultural Biogas Plants explosion, the rolling sphere radius is 30 m (Figure 9.3.2).

define that e.g. Ex zone 2 is located in a radius of 3 m around Depending on the gas volume, the inner membranes in the

the foil roof of the fermenter. In Ex zone 2 potentially explo- gas storage tank of the fermenter contact the metal inner

sive atmospheres only occur occasionally or for a short period wall of the fermenter. An insulated down conductor is used to

of time. This means that a potentially explosive atmosphere is avoid uncontrolled flashover from the down conductor to the

only to be expected in case of rare and unpredictable events metal wall of the fermenter. The lightning protection system

(failure and maintenance work). Therefore, air-termination sys- is electrically isolated from conductive parts of the fermenter

tems may be positioned in Ex zone 2 according to IEC 62305-3 since the down conductor is routed separately by means of

(EN 62305-3). spacers made GRP (glass-fibre reinforced plastic). The length

The rolling sphere method is used to determine the height of the spacers depends on the separation distance determined

and number of air-termination systems. The sag of the rolling according to IEC 62305-3 (EN 62305-3).

276 LIGHTNING PROTECTION GUIDE www.dehn-international.com