Page 793 - ABB_Motor _Protection_and_Control_catalogue_20221216

P. 793

ABB MOTOR PROTECTION AND CONTROL 7/3

—

Thermistor motor protection relays

Applications

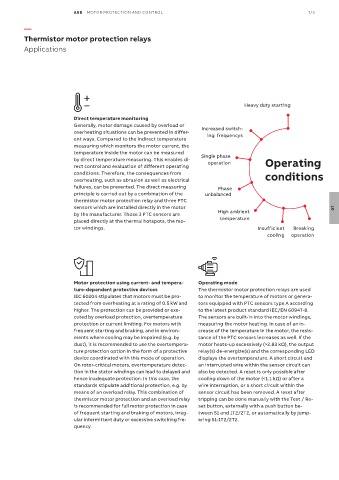

Heavy duty starting

Direct temperature monitoring

Generally, motor damage caused by overload or Increased switch-

overheating situations can be prevented in differ- ing frequencys

ent ways. Compared to the indirect temperature

measuring which monitors the motor current, the

temperature inside the motor can be measured

by direct temperature measuring. This enables di- Single phase Operating

rect control and evaluation of different operating operation

conditions. Therefore, the consequences from conditions

overheating, such as abrasion as well as electrical

failures, can be prevented. The direct measuring Phase

principle is carried out by a combination of the unbalanced

thermistor motor protection relay and three PTC

sensors which are installed directly in the motor 07

by the manufacturer. Those 3 PTC sensors are High ambient

placed directly at the thermal hotspots, the mo- temperature

tor windings. Insufficient Breaking

cooling operation

Motor protection using current- and tempera- Operating mode

ture-dependent protective devices The thermistor motor protection relays are used

IEC 60204 stipulates that motors must be pro- to monitor the temperature of motors or genera-

tected from overheating at a rating of 0.5 kW and tors equipped with PTC sensors type A according

higher. The protection can be provided or exe- to the latest product standard IEC/EN 60947-8.

cuted by overload protection, overtemperature The sensors are built-in into the motor windings,

protection or current limiting. For motors with measuring the motor heating. In case of an in-

frequent starting and braking, and in environ- crease of the temperature in the motor, the resis-

ments where cooling may be impaired (e.g. by tance of the PTC sensors increases as well. If the

dust), it is recommended to use the overtempera- motor heats-up excessively (>2.83 kΩ), the output

ture protection option in the form of a protective relay(s) de-energize(s) and the corresponding LED

device coordinated with this mode of operation. displays the overtemperature. A short circuit and

On rotor-critical motors, overtemperature detec- an interrupted wire within the sensor circuit can

tion in the stator windings can lead to delayed and also be detected. A reset is only possible after

hence inadequate protection. In this case, the cooling down of the motor (<1.1 kΩ) or after a

standards stipulate additional protection, e.g. by wire interruption, or a short circuit within the

means of an overload relay. This combination of sensor circuit has been removed. A reset after

thermistor motor protection and an overload relay tripping can be done manually with the Test / Re-

is recommended for full motor protection in case set button, externally with a push button be-

of frequent starting and braking of motors, irreg- tween S1 and 1T2/2T2, or automatically by jump-

ular intermittent duty or excessive switching fre- ering S1-1T2/2T2.

quency.