Page 143 - 35_DS702_E_2014_Lightning_Protection_Guide

P. 143

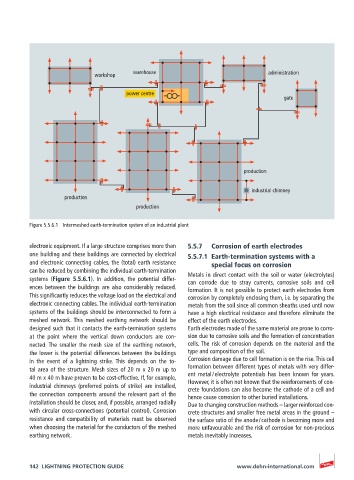

workshop warehouse administration

power centre

gate

production

industrial chimney

production

production

Figure 5.5.6.1 Intermeshed earth-termination system of an industrial plant

electronic equipment. If a large structure comprises more than 5.5.7 Corrosion of earth electrodes

one building and these buildings are connected by electrical 5.5.7.1 Earth-termination systems with a

and electronic connecting cables, the (total) earth resistance special focus on corrosion

can be reduced by combining the individual earth-termination Metals in direct contact with the soil or water (electrolytes)

systems (Figure 5.5.6.1). In addition, the potential differ- can corrode due to stray currents, corrosive soils and cell

ences between the buildings are also considerably reduced. formation. It is not possible to protect earth electrodes from

This significantly reduces the voltage load on the electrical and corrosion by completely enclosing them, i.e. by separating the

electronic connecting cables. The individual earth-termination metals from the soil since all common sheaths used until now

systems of the buildings should be interconnected to form a have a high electrical resistance and therefore eliminate the

meshed network. This meshed earthing network should be effect of the earth electrodes.

designed such that it contacts the earth-termination systems Earth electrodes made of the same material are prone to corro-

at the point where the vertical down conductors are con- sion due to corrosive soils and the formation of concentration

nected. The smaller the mesh size of the earthing network, cells. The risk of corrosion depends on the material and the

the lower is the potential differences between the buildings type and composition of the soil.

in the event of a lightning strike. This depends on the to- Corrosion damage due to cell formation is on the rise. This cell

tal area of the structure. Mesh sizes of 20 m x 20 m up to formation between different types of metals with very differ-

40 m x 40 m have proven to be cost-effective. If, for example, ent metal / electrolyte potentials has been known for years.

However, it is often not known that the reinforcements of con-

industrial chimneys (preferred points of strike) are installed, crete foundations can also become the cathode of a cell and

the connection components around the relevant part of the hence cause corrosion to other buried installations.

installation should be closer, and, if possible, arranged radially Due to changing construction methods – larger reinforced con-

with circular cross-connections (potential control). Corrosion crete structures and smaller free metal areas in the ground –

resistance and compatibility of materials must be observed the surface ratio of the anode / cathode is becoming more and

when choosing the material for the conductors of the meshed more unfavourable and the risk of corrosion for non-precious

earthing network. metals inevitably increases.

142 LIGHTNING PROTECTION GUIDE www.dehn-international.com