Page 139 - 35_DS702_E_2014_Lightning_Protection_Guide

P. 139

foam glass gravel in the excavation pit, the excavation pit is to use a spacer due to the high-density subgrade (wet mix

covered with e.g. geotextiles. aggregate with rocks, etc.).

To be able to install a standard-compliant earth-termination Reinforced strip foundations

system for this type of perimeter insulation, the ring earth elec- In case of reinforced strip foundations, the foundation earth

trode must be installed in contact with the soil below the foam electrode is embedded in concrete as a closed ring. The rein-

glass gravel and geotextiles. Thus, compared to conventional forcement is also integrated and connected in such a way that

methods, the earth electrode is installed at an earlier stage. The it is permanently conductive. Due to the risk of corrosion, it

responsible company must be aware of the fact that the instal- must be observed that the foundation earth electrode is cov-

lation of the earth electrode must be incorporated at an early ered by a concrete layer of 5 cm. The connection components /

design stage, namely directly after the excavation work. Stain- terminal lugs must be made of stainless steel (V4A).

less steel (V4A), e.g. material No. AISI/ASTM 316 Ti, must be

used for the round or flat conductor as well as for the required Steel fibre concrete

clamps and connectors which are directly installed in the soil. Steel fibre concrete is a material which is produced by adding

Also in this case, the functional equipotential bonding conduc- steel fibres to the fresh concrete. In comparison to concrete

tor must be installed in the foundation (see “White tank”). without fibres, steel fibre concrete may be subjected to tensile

force (tensile strength) within certain limits so that the com-

Pad foundations / point foundations monly used concrete steel reinforcement can be completely

Pad foundations, also referred to as point foundations, are of- replaced in many cases. Steel fibre concrete foundations are

ten used for industrial buildings. These pad foundations serve made on site (cast or pumped).

as a foundation, e.g. for steel supports or concrete beams of

halls. The foundation slab is not closed. Since these structures

also require a functioning earth-termination system, earthing

measures are required for these pad foundations.

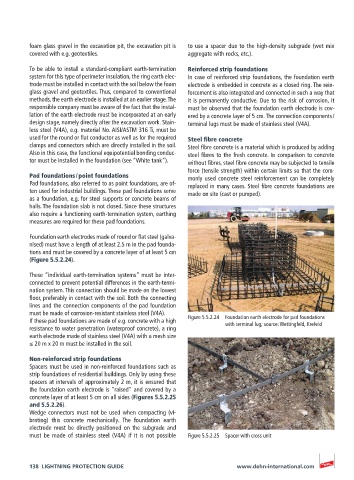

Foundation earth electrodes made of round or flat steel (galva-

nised) must have a length of at least 2.5 m in the pad founda-

tions and must be covered by a concrete layer of at least 5 cm

(Figure 5.5.2.24).

These “individual earth-termination systems” must be inter-

connected to prevent potential differences in the earth-termi-

nation system. This connection should be made on the lowest

floor, preferably in contact with the soil. Both the connecting

lines and the connection components of the pad foundation

must be made of corrosion-resistant stainless steel (V4A).

If these pad foundations are made of e.g. concrete with a high Figure 5.5.2.24 Foundation earth electrode for pad foundations

with terminal lug; source: Wettingfeld, Krefeld

resistance to water penetration (waterproof concrete), a ring

earth electrode made of stainless steel (V4A) with a mesh size

≤ 20 m x 20 m must be installed in the soil.

Non-reinforced strip foundations

Spacers must be used in non-reinforced foundations such as

strip foundations of residential buildings. Only by using these

spacers at intervals of approximately 2 m, it is ensured that

the foundation earth electrode is “raised” and covered by a

concrete layer of at least 5 cm on all sides (Figures 5.5.2.25

and 5.5.2.26).

Wedge connectors must not be used when compacting (vi-

brating) this concrete mechanically. The foundation earth

electrode must be directly positioned on the subgrade and

must be made of stainless steel (V4A) if it is not possible Figure 5.5.2.25 Spacer with cross unit

138 LIGHTNING PROTECTION GUIDE www.dehn-international.com