Page 377 - 35_DS702_E_2014_Lightning_Protection_Guide

P. 377

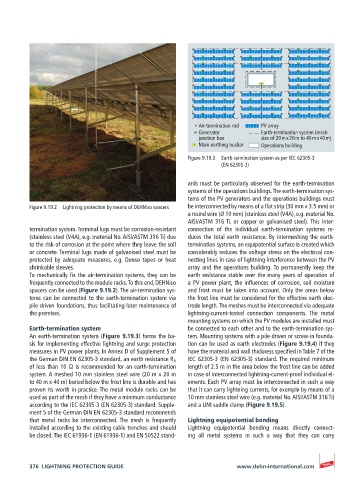

Air-termination rod PV array

Generator Earth-termination system (mesh

junction box size of 20 m x 20 m to 40 m x 40 m)

Main earthing busbar Operations building

Figure 9.19.3 Earth-termination system as per IEC 62305-3

(EN 62305-3)

ards must be particularly observed for the earth-termination

systems of the operations buildings. The earth-termination sys-

tems of the PV generators and the operations buildings must

Figure 9.19.2 Lightning protection by means of DEHNiso spacers be interconnected by means of a flat strip (30 mm x 3.5 mm) or

a round wire (Ø 10 mm) (stainless steel (V4A), e.g. material No.

AISI/ASTM 316 Ti, or copper or galvanised steel). This inter-

termination system. Terminal lugs must be corrosion-resistant connection of the individual earth-termination systems re-

(stainless steel (V4A), e.g. material No. AISI/ASTM 316 Ti) due duces the total earth resistance. By intermeshing the earth-

to the risk of corrosion at the point where they leave the soil termination systems, an equipotential surface is created which

or concrete. Terminal lugs made of galvanised steel must be considerably reduces the voltage stress on the electrical con-

protected by adequate measures, e.g. Denso tapes or heat necting lines in case of lightning interference between the PV

shrinkable sleeves. array and the operations building. To permanently keep the

To mechanically fix the air-termination systems, they can be earth resistance stable over the many years of operation of

frequently connected to the module racks. To this end, DEHNiso a PV power plant, the influences of corrosion, soil moisture

spacers can be used (Figure 9.19.2). The air-termination sys- and frost must be taken into account. Only the areas below

tems can be connected to the earth-termination system via the frost line must be considered for the effective earth elec-

pile-driven foundations, thus facilitating later maintenance of trode length. The meshes must be interconnected via adequate

the premises. lightning-current-tested connection components. The metal

mounting systems on which the PV modules are installed must

Earth-termination system be connected to each other and to the earth-termination sys-

An earth-termination system (Figure 9.19.3) forms the ba- tem. Mounting systems with a pile-driven or screw-in founda-

sis for implementing effective lightning and surge protection tion can be used as earth electrodes (Figure 9.19.4) if they

measures in PV power plants. In Annex D of Supplement 5 of have the material and wall thickness specified in Table 7 of the

the German DIN EN 62305-3 standard, an earth resistance R A IEC 62305-3 (EN 62305-3) standard. The required minimum

of less than 10 Ω is recommended for an earth-termination length of 2.5 m in the area below the frost line can be added

system. A meshed 10 mm stainless steel wire (20 m x 20 m in case of interconnected lightning-current-proof individual el-

to 40 m x 40 m) buried below the frost line is durable and has ements. Each PV array must be interconnected in such a way

proven its worth in practice. The metal module racks can be that it can carry lightning currents, for example by means of a

used as part of the mesh if they have a minimum conductance 10 mm stainless steel wire (e.g. material No. AISI/ASTM 316 Ti)

according to the IEC 62305-3 (EN 62305-3) standard. Supple- and a UNI saddle clamp (Figure 9.19.5).

ment 5 of the German DIN EN 62305-3 standard recommends

that metal racks be interconnected. The mesh is frequently Lightning equipotential bonding

installed according to the existing cable trenches and should Lightning equipotential bonding means directly connect-

be closed. The IEC 61936-1 (EN 61936-1) and EN 50522 stand- ing all metal systems in such a way that they can carry

376 LIGHTNING PROTECTION GUIDE www.dehn-international.com